Experience Superior Security With Ceramic Coatings: an Extensive Summary

Ceramic finishings have emerged as a sophisticated remedy for those seeking enhanced protection for auto and commercial surface areas. As we discover the complex benefits, application methods, and how they pile up versus standard choices, it ends up being evident that the investment in ceramic coverings can redefine your method to surface area security.

What Are Ceramic Coatings?

Ceramic finishings are sophisticated protective layers used to surfaces, mainly in automotive and commercial applications, to boost sturdiness and resistance to environmental aspects. Made up of silicon dioxide (SiO2) obtained from all-natural materials, these layers develop a solid, hydrophobic layer that bonds chemically with the substratum, creating a resistant shield against numerous aggressors such as UV rays, chemicals, and physical abrasions.

The application process normally involves thorough cleaning and prep work of the surface area, followed by the accurate application of the ceramic finishing. As soon as cured, the covering sets right into a durable layer that can dramatically prolong the life expectancy of the surface area it protects. Unlike traditional waxes or sealants, ceramic coverings provide a durable service that requires very little maintenance.

These coverings are not limited to automobile coatings; they are additionally used in aquatic, aerospace, and commercial setups, where they supply considerable advantages in terms of performance and long life. Their adaptability and effectiveness in securing surface areas against deterioration make ceramic coverings a progressively preferred option for both professionals and enthusiasts seeking to keep the integrity and look of useful properties.

Advantages of Ceramic Coatings

In addition, ceramic finishings show exceptional hydrophobic properties, permitting water and other fluids to bead up and roll off surface areas - Orlando Car Care Ceramic Coatings. This self-cleaning impact considerably reduces the moment and initiative required for maintenance, as dust and grime are less likely to stick. Furthermore, ceramic finishings are immune to engraving and scraping, which even more protects the integrity of the underlying surface area

One more critical advantage is the thermal resistance provided by ceramic finishings, which can withstand high temperature levels without breaking down. This quality is specifically beneficial for auto applications, where engine parts and exhaust systems go through severe warmth.

Application Process Clarified

Attaining ideal outcomes with ceramic layers requires a careful application procedure that guarantees proper adhesion and efficiency. For automotive applications, repaint correction might be necessary to attend to flaws, making certain the surface area is as flawless as possible.

As soon as the surface area is prepared, it is important to apply the ceramic finishing in a regulated setting, ideally in see here now a garage or shaded location to stay clear of straight sunshine and dust. Making use of a foam applicator or a microfiber towel, the finish should be applied evenly in small sections, permitting optimum control throughout application. A curing time of around one to 2 hours is advised before exposing the surface to moisture.

After the first healing, multiple layers may be related to boost longevity and gloss, with each layer calling for sufficient treating time. Finally, it is essential to examine the surface for any high areas or uneven application and to buff these areas as necessary, making sure a remarkable coating that optimizes the safety benefits of the covering.

Upkeep Tips for Longevity

Correct upkeep is vital to maximizing the long life of ceramic finishes, guaranteeing that the safety layer proceeds to carry out effectively gradually. Regular cleaning is important; use a pH-balanced, mild soap and a microfiber wash glove to avoid damaging the surface area. If exposed to rough aspects., it is suggested to wash the vehicle every two weeks or even more frequently.

After washing, extensively dry the surface area with a clean microfiber towel to avoid water areas. In addition, using a ceramic maintenance spray every few months can restore the covering's hydrophobic properties, boosting security versus contaminants.

Prevent making use of abrasive cleaning devices, waxes, or sealers that might degrade the ceramic layer. Instead, choose non-abrasive products particularly made for ceramic layers.

Inspect the finish periodically for any type of indications of wear or damages, and address these concerns promptly to maintain optimal efficiency.

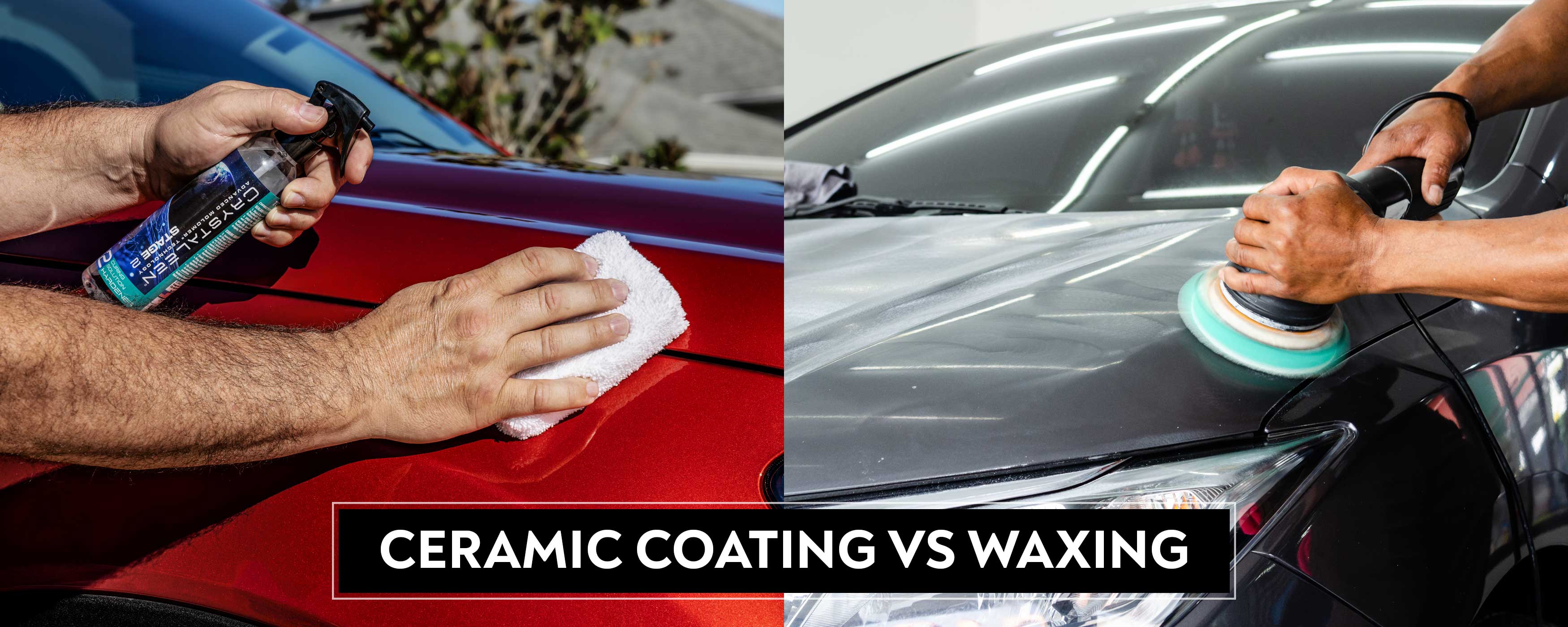

Comparing Ceramic Coatings to Alternatives

Preserving ceramic finishes is simply one facet to take into consideration when examining safety alternatives for vehicle surfaces. When contrasting ceramic coatings to alternatives such as wax, sealants, and paint protection films, several critical elements emerge.

Paint protection movies (PPF) are one more prominent option, giving superb physical security against scrapes and chips. Nonetheless, they can be a lot more costly and might need professional installment, unlike ceramic coatings, which can typically be applied by an experienced do it yourself enthusiast. Furthermore, ceramic finishings enhance the vehicle's gloss and depth, supplying visual benefits that options might not match.

Conclusion

In verdict, ceramic coverings represent a substantial innovation in surface defense for automotive and commercial applications. With marginal maintenance demands and lasting efficiency, ceramic coatings not only protect the honesty of surfaces yet additionally enhance their visual appeal.

Comments on “The Best Choice for Your Vehicle: Orlando Car Care Ceramic Coatings”